Highland Machine Helped Aeragen Design and Manufacture a Groundbreaking Device to Protect Healthcare Frontline Staff

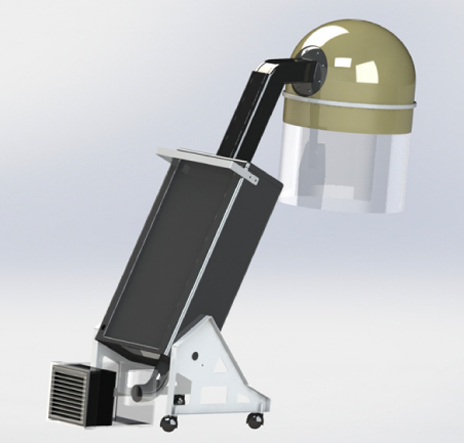

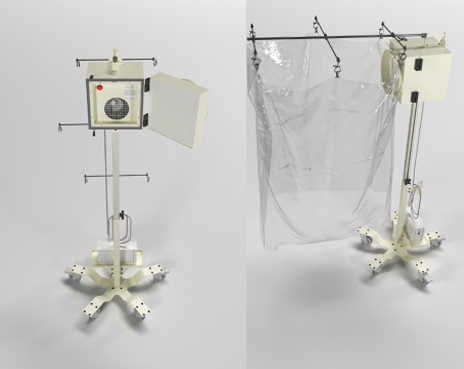

Aeragen traces its origins to an interdisciplinary COVID-19 task force team comprised of healthcare providers, university professors, and students formed in March 2020 at New York University. In mid April, 2020, they came to Highland Machine with an idea for the initial prototype for mobile isolation units. It would work by reversing the functionality of a hair dryer, removing air from the hood instead of into the hood as it would do to dry hair. Since then, the two teams have continued to work together to iterate the design, build prototypes, and develop an end-to-end process for the manufacturing, packaging, storing, and shipping of the product.

Challenge

The mission of the NYU task force was to design a device that could reduce the viral load healthcare workers are exposed to while treating a COVID-19 patient. There were two primary challenges in accomplishing this goal. The first was to build a device that could effectively remove pathogens from the air. The second was to find a partner that could help them scale production of the device.

Working with an end-to-end manufacturer

“Highland Machine has been phenomenal since we started working with them. They really understand what we are trying to do and have worked hard to help make it possible. It’s been awesome to partner with a company that understands the value of our mission and what we’re trying to do. Having a whole design and manufacturing team behind us has been invaluable, and Highland helps us with the design, prototyping, manufacturing, packaging, storing, and shipping. On top of that, we have a great relationship with them. Our calls are fun and productive.”

– Tom Sowers, Co-Founder, Aeragen

Solution

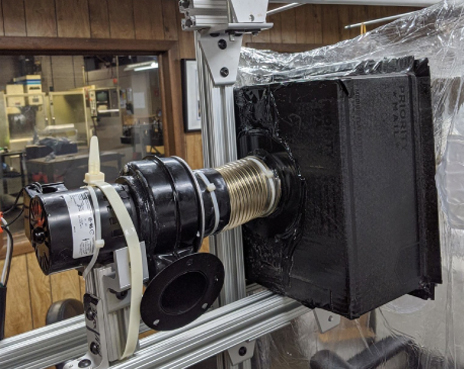

The solution was to work with Highland Machine. After contacting several other manufacturers, Aeragen found Highland’s salon hair dryer online and thought its design would be perfect as a starting point for their product. They contacted Highland Machine, and they received a prototype within 48 hours that proved the concept could work.

The two groups then worked closely together to refine the design multiple times and to build several more prototypes. Together, they found ways to increase the size of the patient isolation area, to capture and remove pathogens in the area effectively, to reduce the noise levels of the device significantly, to ensure portability, and to accommodate placement over both beds and wheelchairs.

A more effective isolation method

“The healthcare world is quickly realizing that having these big isolation rooms is not the most effective method for isolation. If the patient needs to leave the room, you can’t just pick up the room and bring it with them. Our product lets the technology of the room travel with you wherever you go in the hospital. It’s a solution that moves with the patient and significantly lowers the costs of isolation.”

– Miles Kilcourse, Co-Founder, Aeragen

Outcome

The relationship between Aeragen and Highland Machine has continued to evolve with Aeragen’s needs, from initial proof of concept prototypes through the first production run of the AerVent in anticipation of Aeragen’s Emergency Use Authorization by the FDA. The result is a product designed, not just for the end user, but for the manufacturer to deliver the solution in quantities desperately needed by the healthcare industry. Together, Aeragen and Highland Machine have created individual patient isolation units to greatly increase the isolation capacity of hospitals that may not have the necessary resources to build large isolation rooms and wings. With mobile, cost effective isolation capabilities, hospitals can deliver care safer and sooner than ever before.

Aeragen is working with hospitals throughout the U.S. to begin installing their product once they receive final FDA approval. With the manufacturing expertise of Highland Machine behind them, Aeragen will be able to scale up production quickly as the number of medical facilities that want to purchase the device increases.

A flexible, experienced partner

“A lot of metal manufacturers don’t design with clients. But that’s something that we have the tools, skills, and capabilities to do. We worked with Aeragen from the beginning stages of their project and once it’s approved, we can deliver the capacity they need to meet their sales. We took the time to seriously look into their idea when other manufacturers wouldn’t because this product will save lives. We believed in their idea at the beginning, and we believe in it now.”

– Bill Sullivan, President and CEO, Highland Machine

Stay up-to-date with Highland Machine

Join our emailing list to receive product updates, company news, blog articles, and more.

700 5th St., Highland, IL 62249 • 618-654-2103 • info@highlandmachine.com

All content copyright © Highland Machine