When manufacturing electrical components and electronics, the key factors to ensure performance are precision and protection. The different parts inside control systems, circuit boards, power distribution panels, and electronic enclosures must fit together flawlessly for the device to function properly. They must also be compact and relatively lightweight. Sheet metal fabrication satisfies these requirements, which is why it’s used to manufacture a wide variety of products and components in the electronics industry.

At Highland Machine, we specialize in precision sheet metal fabrication that delivers accuracy, consistency, and quality, whether it’s a single prototype enclosure or thousands of finished assemblies.

How Sheet Metal Fabrication Powers the Electrical Industry

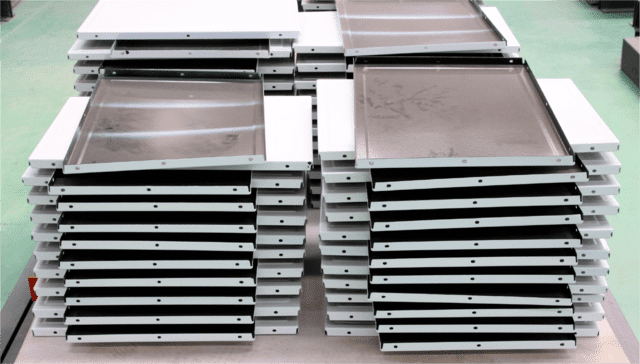

Fabrication is widely used to build sheet metal enclosures and electrical housings. It gives you the ability to manufacture parts that are small enough to fit in tight spaces but strong enough to shield sensitive inner components. Common applications of sheet metal fabrication in the electronics industry include:

- Enclosures and cabinets that protect control systems, switchgear, circuit boards, and more.

- Racks, panels, and mounting plates that organize and support hardware.

- Fan, duct, and ventilation components for regulating temperature.

- Brackets, frames, and guards for creating assemblies and protection.

- Shielding and covers that defend against electromagnetic interference (EMI).

Customization, Flexibility, and Precision

No two electrical assemblies are exactly the same, which means custom fabrication is essential. Sheet metal can be formed into extremely thin, lightweight parts that fit precisely in the small areas found on most electronic devices. Plus, openings can be easily cut for ventilation, wiring, displays, and ports, while bends and flanges can be adjusted for mounting hardware or connectors.

At Highland Machine, we use laser cutting, CNC punching, TIG, MIG, and spot welding, and forming, and other advanced methods to ensure that every electrical component meets exact specifications with tight tolerances. Whether you need prototypes, low volume custom runs, or full scale production, our team can create consistent, high quality parts that integrate seamlessly within your designs.

Versatility in Materials

Another reason why sheet metal fabrication in the electrical industry is so common is because it can be used with a wide range of metals, including:

- Aluminum is lightweight, naturally corrosion resistant, and is well suited to being cut, welded, and joined, ideal for electrical applications.

- Stainless steel provides strength and resistance to things like moisture and chemicals, important for outdoor or industrial environments. It also has high conductivity and formability, which are important for electronics.

- Cold rolled and galvanized steel offer a balance between durability and cost efficiency, making them popular for large sheet metal enclosures and electrical cabinet production.

- Copper and brass have excellent thermal conductivity, perfect for heat exchangers, are great electrical conductors, and are very malleable.

EMI Shielding and Electrical Protection

One of the most valuable advantages of sheet metal fabrication in electronics is its ability to provide EMI (electromagnetic interference) shielding. Electrical systems can generate or be affected by unwanted interference, which can disrupt performance or cause component failure.

Sheet metal enclosures act as a protective barrier, blocking electromagnetic fields and keeping signals stable. Materials like copper, aluminum, and certain steel alloys can be engineered to optimize electrical conductivity or resistance, depending on shielding needs and requirements of your project. Combined with precision forming and grounding techniques, fabricated enclosures can meet strict industry standards for electromagnetic compatibility (EMC).

Finishes and Coatings for Electrical Assemblies

Beyond the base metal, the finish of each component plays an important role in performance and appearance, particularly in the electronics industry. At Highland Machine, we offer a wide selection of metal finishing options, including:

- Powder coating and painting for corrosion resistant and aesthetics.

- Anodizing for aluminum parts to increase surface hardness and conductivity.

- Plating and chemical conversion coatings for improved electrical conductivity or insulation.

- Protective films and labeling for safety and identification.

These finishing processes enhance both the functional and visual qualities of fabricated components, ensuring they perform reliably and look professional.

Why Work With Highland Machine for Electrical Sheet Metal Fabrication

Highland Machine offers end-to-end fabrication services, meaning we handle your entire project from start to finish. With decades of experience within the electronics, medical, aerospace, and automotive industries, our team understands the precision, workmanship, and dependability required to keep critical components and systems working. By partnering with Highland Machine, you gain:

- A single provider for designing, fabrication, finishing, assembly, and inventory management

- Reliable quality control and accountability

- Short lead times and lower logistical costs

- Scalable solutions for prototypes, small runs, and full scale production

Contact our team to discuss your next electrical sheet metal fabrication project and request a quote today!