When it comes to launching a new product or increasing your existing production, relying on a contract manufacturer can give your business a strategic advantage that saves you time and money. Instead of investing in your own facilities, equipment, and labor to expand your capacity or capabilities, you can utilize the expertise and experience provided by a specialized manufacturer.

In this article, we’re going to cover what sheet metal and precision machining contract manufacturing are and the top reasons that companies may go this route. Plus, we’ll look at what sets Highland Machine apart from other contract manufacturers.

What is a contract manufacturer?

Similar to outsourcing, contract manufacturing is when one company hires an outside, third party for production. They can do this for a single part, multiple components, or an entire finished product. It’s a popular strategy for smaller operations when they don’t have the capacity or workforce to build something in house, but also for larger companies who may not possess the specialized capabilities to manufacture certain items. In any case, there are several primary reasons why a business will turn to a contract manufacturer.

Why companies choose contract manufacturing

- Cost efficiency

Setting up and operating an in house manufacturing facility can be prohibitively expensive, especially if you’re new to an industry. Through outsourcing, companies avoid the high upfront costs of equipment, space, and labor, and instead pay only for the services they need. - Access to expertise

Contract manufacturers bring specialized knowledge, skilled technicians, and advanced technology to the table—resources that many businesses may not have internally. This access allows you to maintain high quality without developing that expertise in house. - Faster time to market

In competitive industries, speed is critical. Contract manufacturing streamlines the product development process, reducing delays caused by setup, training, or supply chain inefficiencies. Many manufacturers, like Highland Machine, also offer in house prototyping, helping shorten the overall timeline. - Increased adaptability

Contract manufacturing makes it possible for companies to ramp production up or down based on current demand. Whether it’s a small batch or a full scale product line, this flexibility is essential for managing cash flow and adapting to quickly changing markets. - Quality and compliance

Reputable contract manufacturers have established quality control systems and certifications to guarantee consistent results. For example, at Highland Machine, our quality management system is ISO 9001:2015 certified by TÜV Rheinland of North America, which ensures the final product meets your exact specifications. By turning to specialists, businesses can comply with stringent industry regulations and maintain the highest standards.

When should your business utilize contract manufacturing?

Whether or not you should rely on a contract manufacturer for precision machining, sheet metal manufacturing, or anything else comes down to the situation of your particular company. Here are several questions you should ask yourself:

- Are you just starting out? In the early stages of any operation startup costs are high and funds are limited. If you’re a young company, then contract manufacturing may make sense.

- Is demand outpacing capacity? If you have an unexpected surge in demand, it is often smart to partner with a contract manufacturer to meet it effectively.

- Do you want to experiment with a new product format or manufacturing process? Trying out new types of production can be extremely costly. Outsourcing to test new methods can save you time, money, and effort.

- Are you looking to scale but don’t have the capital resources? If your company can’t move beyond a certain level of growth, using a contract manufacturer may help you expand without tying up limited resources.

- Do you have the capability to build what you need? If you don’t have the skills or manpower to create your entire product in house, then you’ll have to hire an outside company.

Why rely on Highland Machine for contract manufacturing?

When it comes to deciding on a precision machining or sheet metal contract manufacturer, you require more than just a supplier. You want a partner who cares about your product, your business, and your success. You also need a company that knows what they’re doing and has a proven track record of quality, craftmanship, and sticking to a timeline. You receive all that and more with Highland Machine. Here is what sets us apart from the competition:

- Turnkey manufacturing: We do more than just precision machining or sheet metal manufacturing. From design and engineering, through prototyping, building, assembly, and inventory management, we handle the entire process in house.

- Custom solutions: We tailor each project to your exact specifications, whether it’s a one off prototype or large scale, ongoing production.

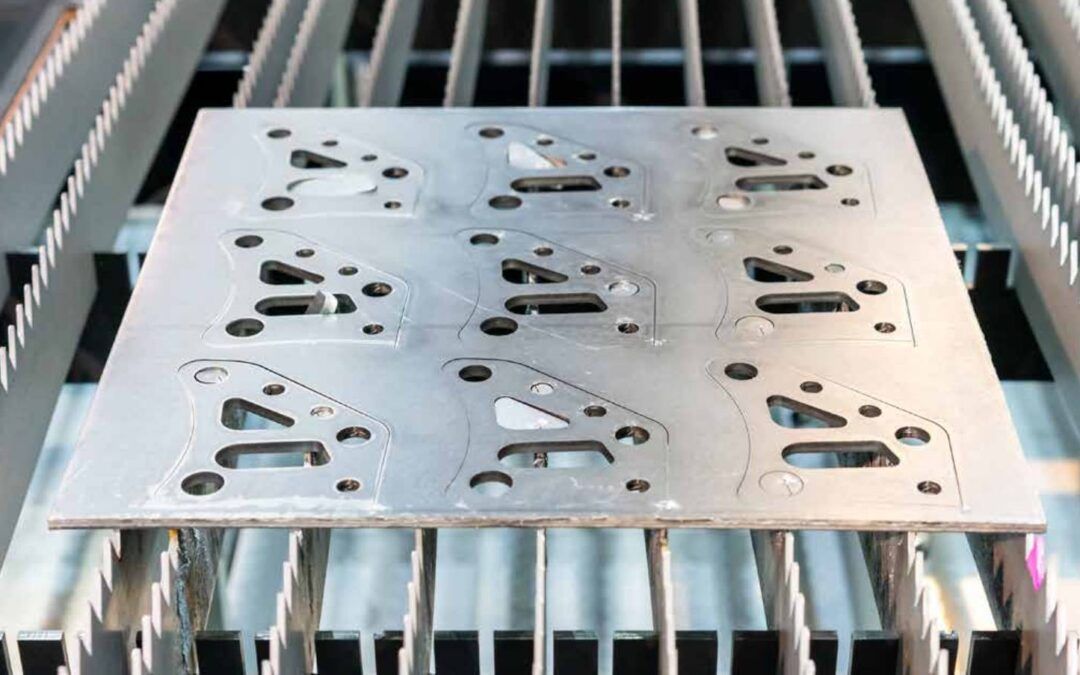

- Advanced capabilities: We utilize state-of-the-art equipment for laser cutting, CNC forming, welding, powder coating, and more.

- We’re a family company with family values: Multiple generations have owned and operated Highland Machine since we were founded in 1944. We take pride in the relationships we’ve built with customers over that time period and the quality we have consistently delivered.

If you’re looking for a turnkey manufacturing partner to take your product and your business to the next level of success, contact our team, and tell us about your project today. We are a contract manufacturer you can depend on.

Request a Quote